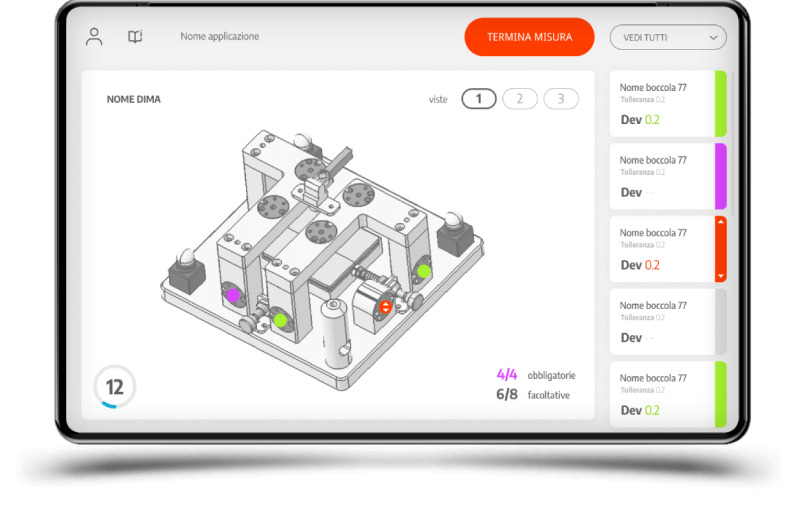

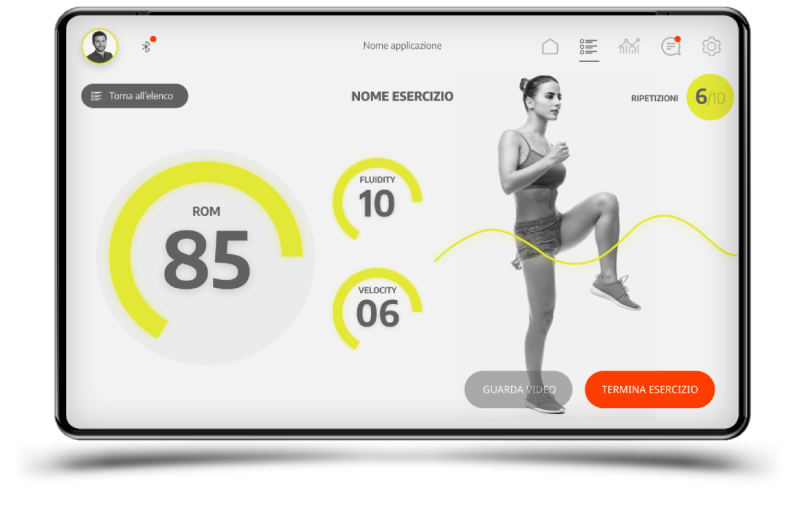

MOBILE (IOS/ANDROID) APP

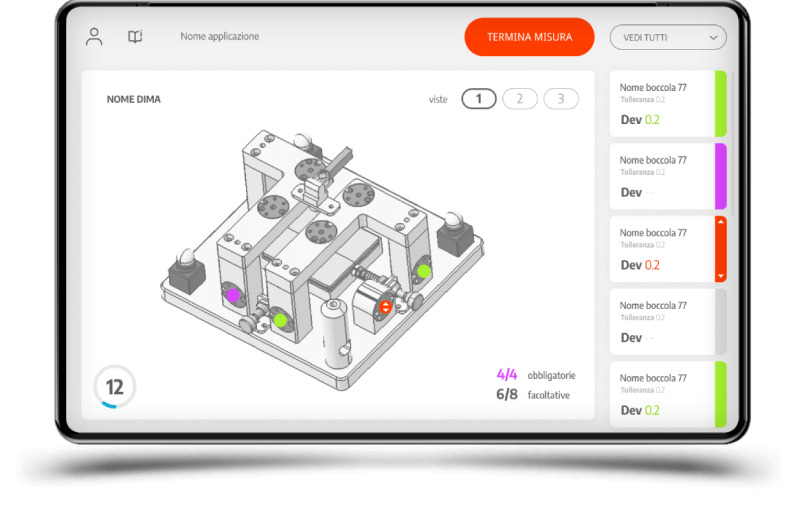

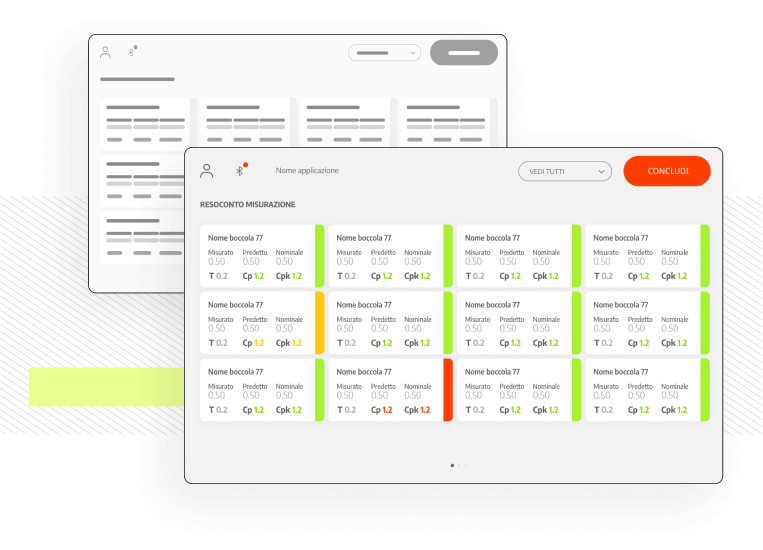

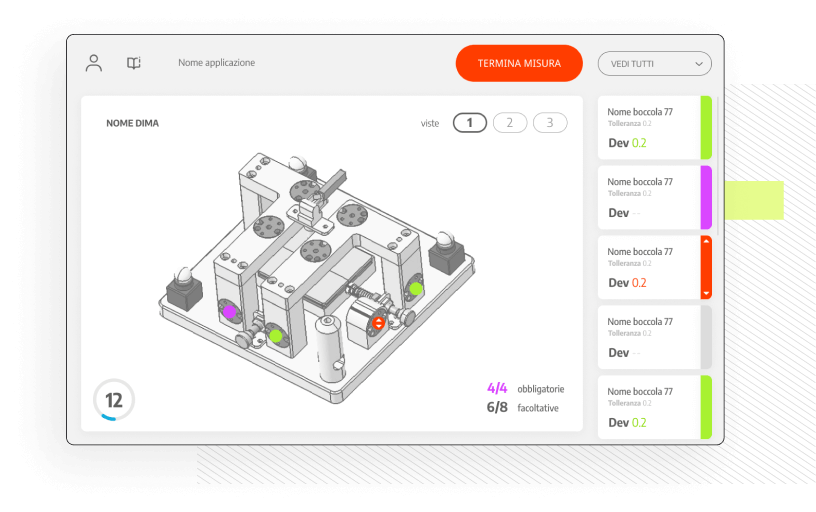

# Measurement control

The customer needed a system to measure, review and control quality data on jigs. This system needed to ensure accuracy and traceability of data, improving the quality control process and ensuring that production met required standards.

New production line + New product + Easy/clean UI + Clear focus + Scalable for many clients

To tackle the project, we started with a series of meetings to fully understand the customer’s needs and habits in using measurement and quality control tools. We placed a strong emphasis on the user experience, analyzing how the customer interacted with existing systems and identifying areas for improvement. This allowed us to design an intuitive and user-friendly solution that seamlessly integrated workflows, improving the efficiency and accuracy of dime quality control.

Event storming + Incremental development + Continuous improvement

To realize the solution, we integrated 3D previews of the models to be measured, highlighting alerts and necessary references directly on the models. This visual approach improved the accuracy and efficiency of quality control.

We also implemented a control system that allows users to check for any issues or deviations from quality parameters. In addition, we developed a sequential measurement function, which guides users through each step of the process, ensuring a complete and systematic verification of the jigs.

User flows + Personas+ Wireframes + Fast Prototype + POC

13ACDC

A8F131

DA46FF

FF3D00

FFFFFF

F2F2F2

61615F

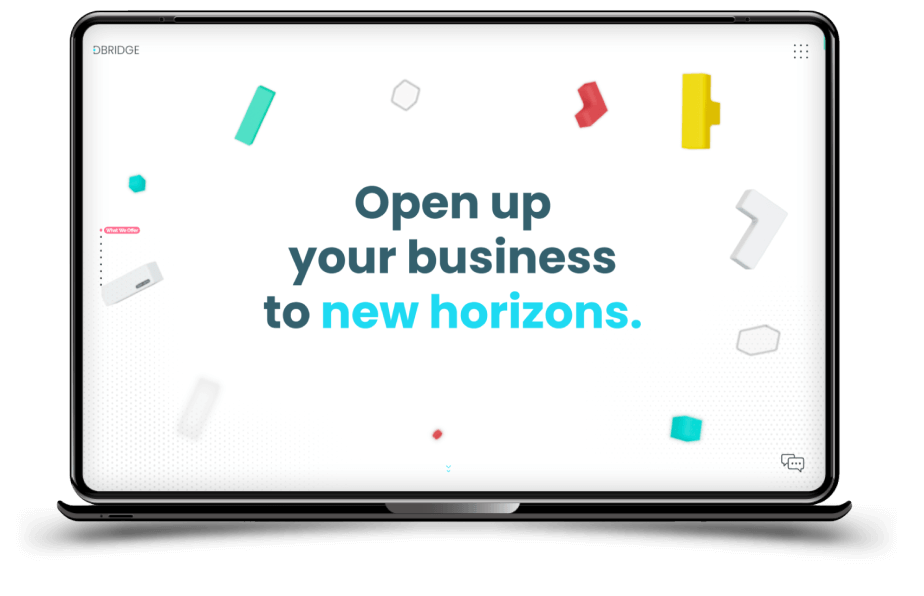

We have accumulated significant experience in developing innovative projects, serving startups, SMEs and large companies. If you don’t believe it, we’re sorry.

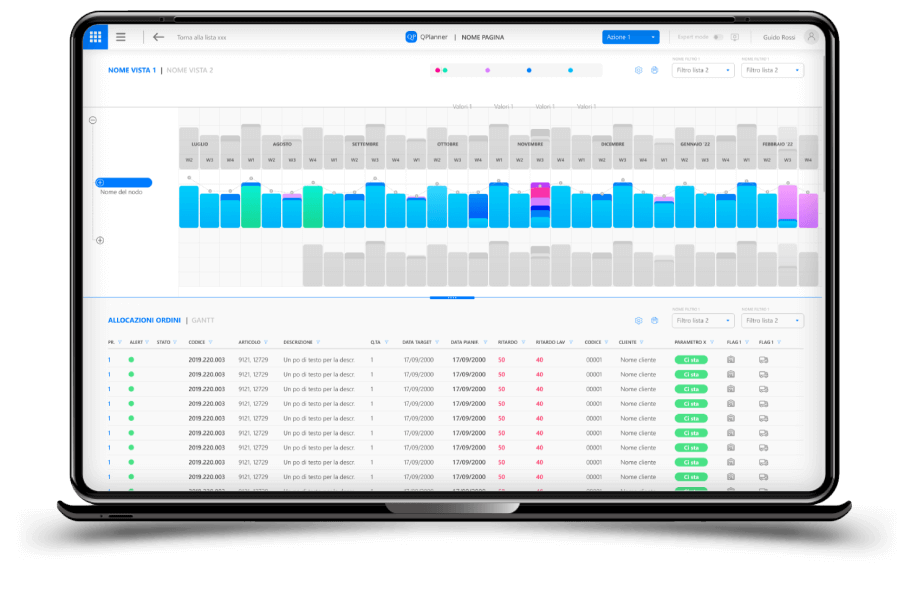

WEB APP

# Company production

MOBILE (IOS/ANDROID) APP

# Measurement control

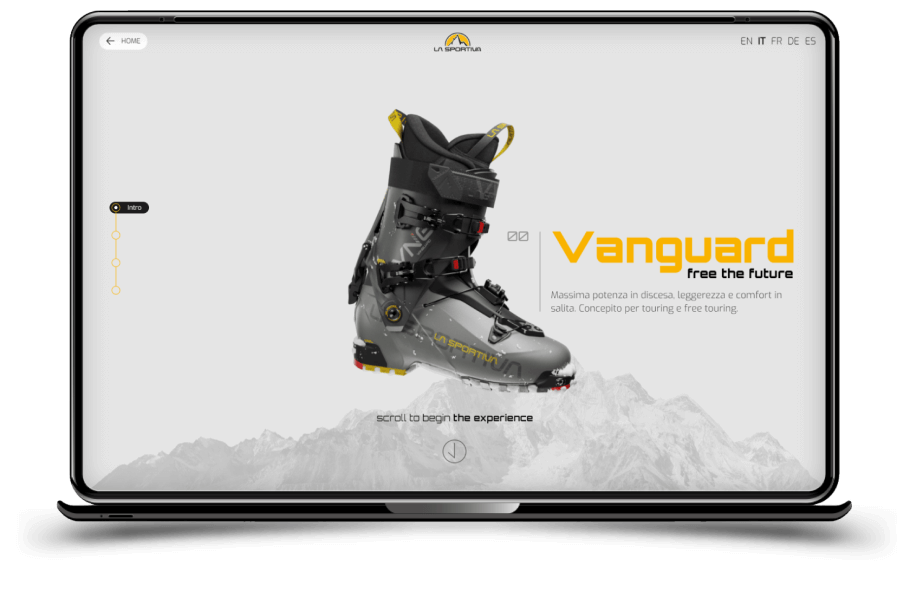

WEBSITE

# Interactive 3D

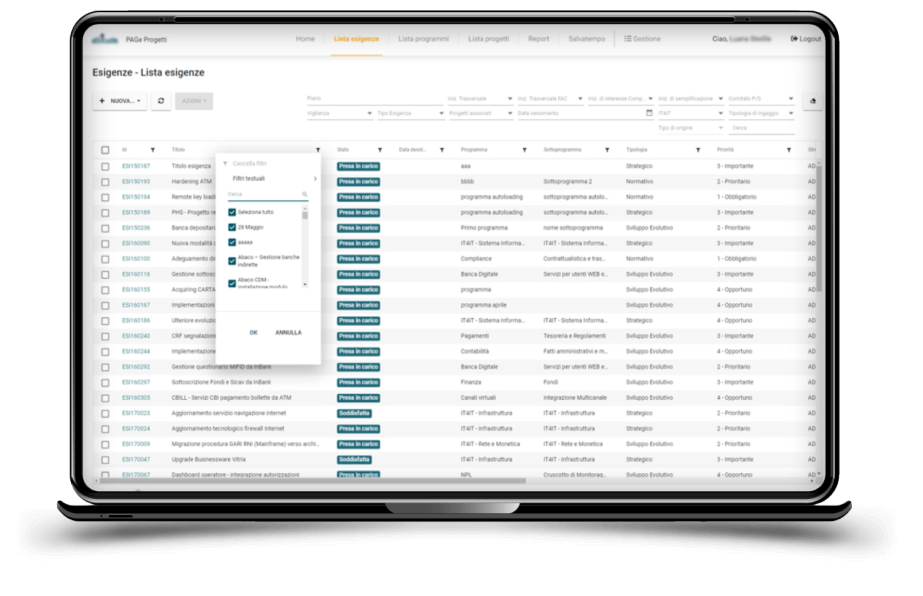

WEB APP

# Computer banking services

WEB APP

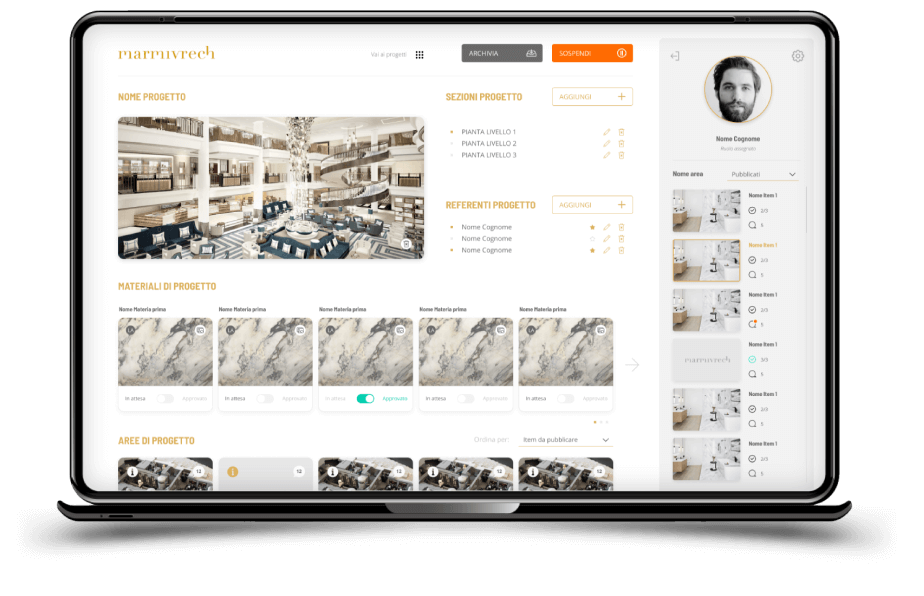

# Design and construction

BRAND + PRODUCT DESIGN

# Alfalfa-based cosmetics

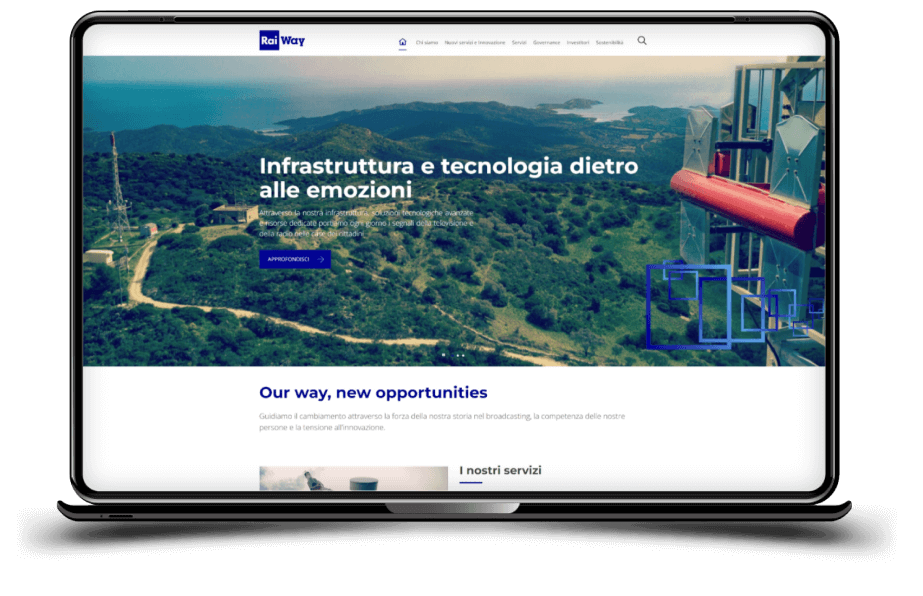

WEBSITE

# Radio and television services

WEB APP

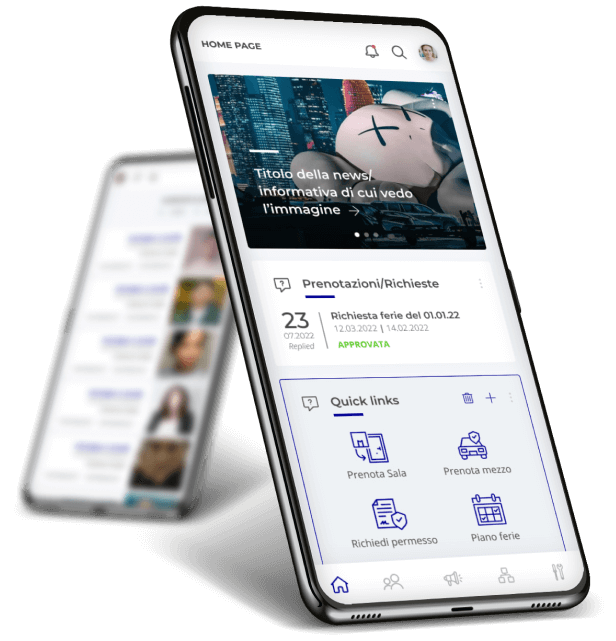

# Corporate Intranet

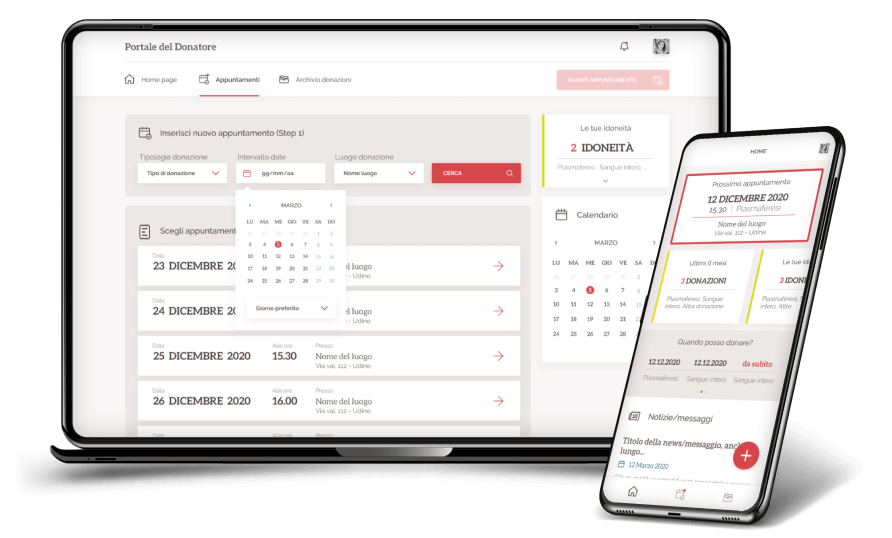

WEB APP + PWA

# Health

WEBSITE

# Silent luxury brand

MOBILE (IOS/ANDROID) APP

# Health

WEBSITE

# Business

PACKAGING

# Silent luxury brand

AUDIO AND 3D VIDEO

# Professional timing

WEB APP

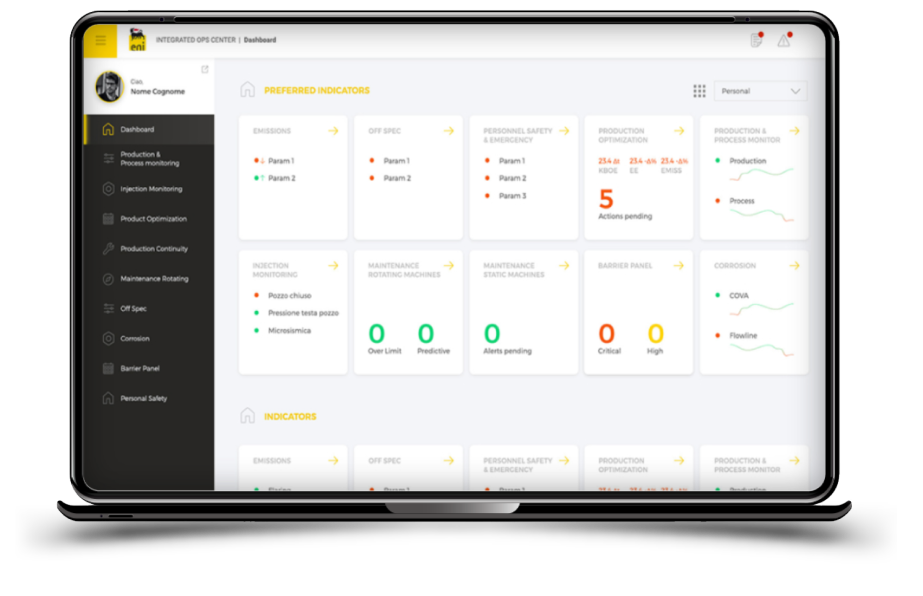

# Oil industry

WEB APP

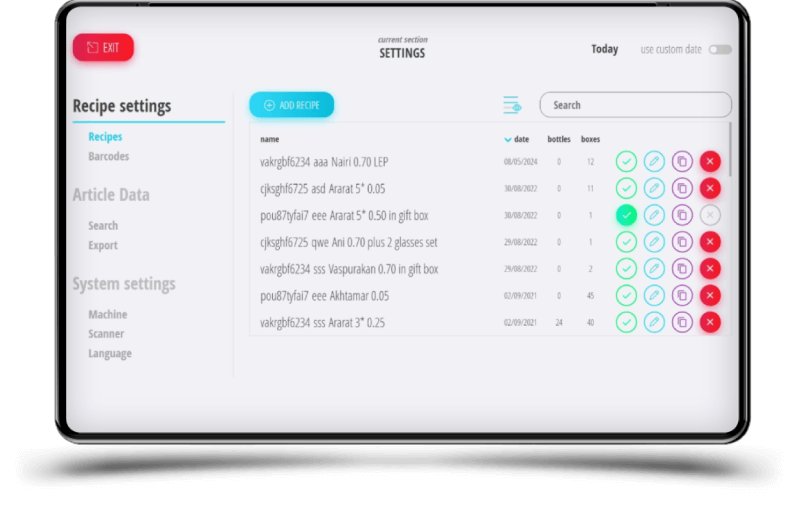

# Manufacturing industry

For any questions or requests

Write to us now!

We don’t bite and we are (almost always) in a good mood